Tavrida Electric factories are assessed by Eskom delegates

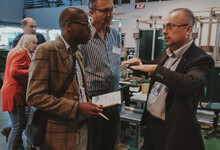

South Africa's largest utility Eskom paid an official visit to Tavrida Electric’s main production sites to perform the Factory Acceptance Testing (FAT) of the Rec25 series Automatic Circuit Reclosers.

The Recloser is a complex protection and automation system, to ensure this system operates reliably, Tavrida Electric manufactures all the critical components in-house. To oversee and check all the production facilities Eskom delegates needed 2 weeks. The evaluation program included both reviewing technical compliance to specification and a review of the quality management system. Our colleagues at the factory were delighted to provide further clarification by answering some interesting commercial questions raised by our guests.

The inspection began at the Switching modules factory where delegates observed the assembly lines and routine testing procedures in accordance with IEEE C37.60/IEC 62271-111. Next stop was the Vacuum interrupters and Electronic modules production facilities where our guests learned about the implemented modern approach in manufacturing and quality assurance measures. Finally, the biggest part of the program at the Completed products factory, here the Eskom representatives witnessed functional testing of the final product. Numerous amount of hardware and software tests were conducted and the results recorded on the report sheets.

This is the second time Eskom have visited Tavrida Electric factories. The first visit was in 2011 and resulted in a strong partnership. Several thousand Tavrida Electric reclosers have been installed across the South African distribution network since then. Eskom has very high standards, and thorough and rigorous selection process for the selection of switchgear equipment, therefore we are very proud that Tavrida Electric manages to impress Eskom with the high quality standards of our production sites.